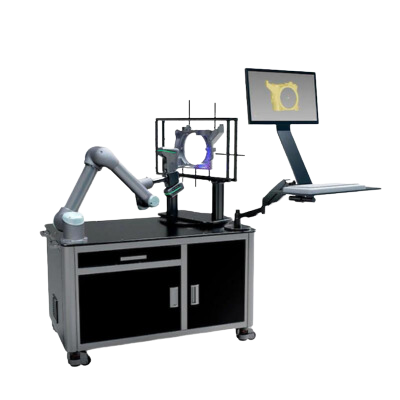

Revolutionize Your Inspection Process

The AutoScan-K series revolutionizes the inspection process with its automatic whole-process capability. Through machine vision technology, it conducts non-contact and non-destructive inspections, scanning and comparing data without human intervention. This automation enhances efficiency, reduces manufacturing costs, and accelerates time-to-market for products.

Personalized Operation

Tailored to meet diverse inspection needs, the AutoScan-K offers personalized operation modes. It adapts to different workpieces’ characteristics by providing multiple measurement modes and enabling inspection routes to be set from various angles. This flexibility ensures thorough and accurate inspections for a wide range of products.

Explore the capabilities of Portable Laser 3D Scanning

With its sleek design and advanced features, SIMSCAN offers an unparalleled scanning experience unlike any other. Say goodbye to cumbersome equipment and hello to effortless precision with SIMSCAN.

AutoScan-K Specifications

| Type: | SIMSCAN 42 | SIMSCAN 30 | SIMSCAN 22 |

|---|---|---|---|

| Scan mode: | 17 blue laser crosses | 11 blue laser crosses | 7 blue laser crosses |

| Accuracy: | Up to 0.020 mm (0.0008 in) | Up to 0.020 mm (0.0008 in) | Up to 0.020 mm (0.0008 in) |

| Scanning rate up to: | 2,800,000 measurements/s | 2,020,000 measurements/s | 1,250,000 measurements/s |

| Scanning area up to: | 700 mm × 600 mm (27.6 in × 23.6 in) | 650 mm × 550 mm (25.6 in × 21.7 in) | 650 mm × 550 mm (25.6 in × 21.7 in) |

| Laser class: | CLASSⅡ (eye-safe) | CLASSⅡ (eye-safe) | CLASSⅡ (eye-safe) |

| Resolution up to: | 0.020 mm (0.0008 in) | 0.020 mm (0.0008 in) | 0.020 mm (0.0008 in) |

| Volume accuracy: | 0.015 mm + 0.035 mm/m (0.0006 in + 0.0004 in/ft) | 0.015 mm + 0.035 mm/m (0.0006 in + 0.0004 in/ft) | 0.015 mm + 0.035 mm/m (0.0006 in + 0.0004 in/ft) |

| Stand-off distance: | 300 mm (11.8 in) | 300 mm (11.8 in) | 300 mm (11.8 in) |

| Depth of field: | 550 mm (21.7 in) | 550 mm (21.7 in) | 550 mm (21.7 in) |

| Output formats: | .stl, .obj, .ply, .asc, .igs, .txt, .mk2, .umk and etc. | .stl, .obj, .ply, .asc, .igs, .txt, .mk2, .umk and etc. | .stl, .obj, .ply, .asc, .igs, .txt, .mk2, .umk and etc. |

| Operating temperature range: | -10℃–40℃ (14℉-104℉) | -10℃–40℃ (14℉-104℉) | -10℃–40℃ (14℉-104℉) |

| Interface mode: | USB 3.0 | USB 3.0 | USB 3.0 |

| Dimensions: | 203 mm × 80 mm × 44 mm (8.0 in × 3.1 in × 1.7 in) | 203 mm × 80 mm × 44 mm (8.0 in × 3.1 in × 1.7 in) | 203 mm × 80 mm × 44 mm (8.0 in × 3.1 in × 1.7 in) |

| Weight: | 570 g (1.26 lb) | 570 g (1.26 lb) | 570 g (1.26 lb) |

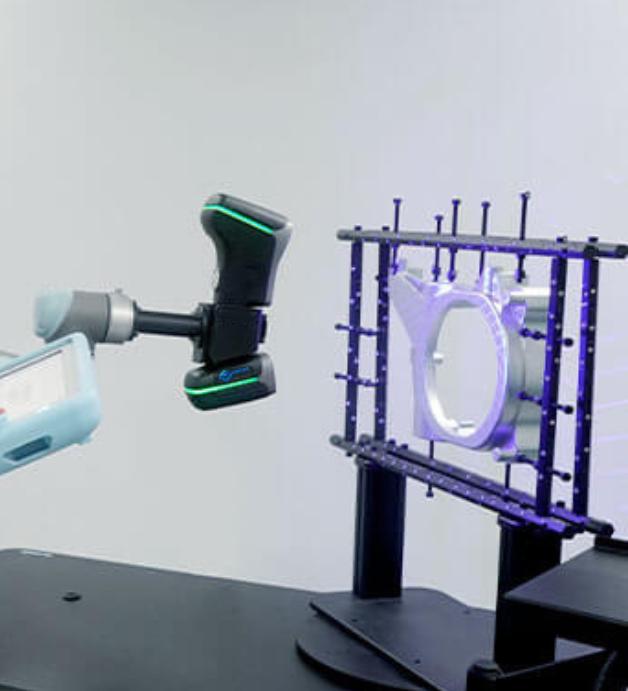

Safe and Reliable NDT

Utilizing automated optical measurement technology, the AutoScan-K ensures safe and reliable non-destructive testing (NDT) in industrial environments. Its intelligent rotary tables facilitate efficient and blind-angle-free inspections, contributing to enhanced productivity and quality assurance.

Precise and Effective Measurement

With its capability to inspect workpieces of varying sizes, weights, and materials, the AutoScan-K delivers precise and effective measurements. Equipped with up to 45 laser lines for high-density scanning, it achieves remarkable speeds of up to 1,650,000 measurements per second. This results in precise 3D inspections even in harsh industrial environments, with exceptional resolution and volume accuracy.

Equipped with multiple working modes, the AutoScan-K 3D system seamlessly adapts to various industrial scenarios. Its versatility allows for precise control over robot movements, facilitating efficient and automatic batch inspections across different manufacturing environments. This adaptability enhances productivity and streamlines inspection processes.

Advanced Machine Vision Technology

The AutoScan-K 3D system leverages advanced machine vision technology to achieve non-contact and non-destructive inspections. This cutting-edge approach ensures exceptional accuracy while enabling efficient batch scanning and inspection operations. With its ability to operate continuously for 24 hours, the system significantly contributes to cost reduction and accelerated time-to-market for products.

Enhanced Precision and Efficiency

By generating up to 45 laser lines for high-density data scanning, the AutoScan-K delivers unparalleled precision and efficiency in measurement. With a scanning speed of up to 1,650,000 measurements per second, it ensures rapid yet accurate 3D inspections, even in challenging industrial settings. The system's exceptional resolution and volume accuracy further optimize quality control procedures, ensuring superior product quality.

Get Your Quote

You have questions, we have the answers. Give us a few details below and we will take care of the rest.

We'd Love To Hear From You

contact us