Precision and Versatility

Engineered for precision and versatility, our comprehensive handheld 3D scanner boasts five distinct modes of operation – large-area scanning with parallel infrared lasers, ultra-fast scanning with blue laser crosses, hyperfine scanning with blue parallel lasers, deep-hole scanning with a single blue laser, and a built-in large-area photogrammetry system.

Five Operating Modes

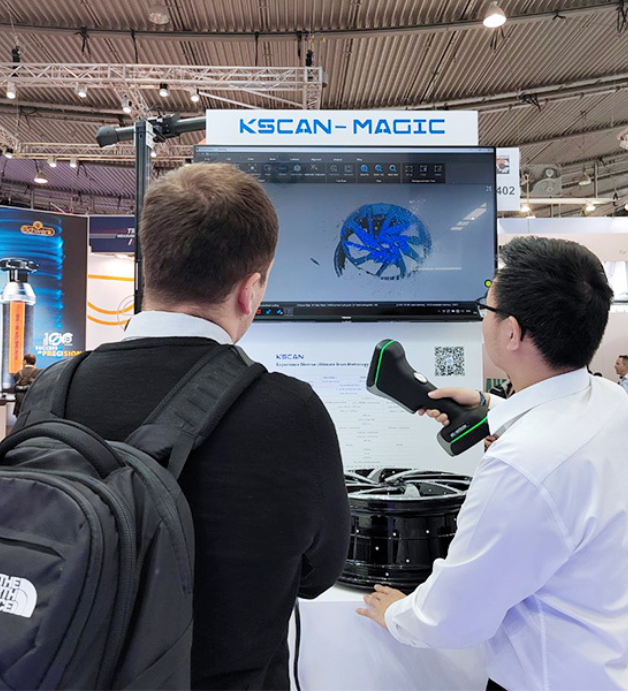

The KSCAN-Magic offers five operating modes to cater to various scanning needs: large-area scanning, ultra-fast scanning, built-in large-area photogrammetry, hyperfine scanning, and deep hole scanning. Each mode is designed to capture precise 3D data in different scenarios.

Explore the capabilities of Built-in Large-area Photogrammetry

The built-in infrared photogrammetry system, with a shooting area of 3760 mm * 3150 mm, can efficiently reduce the accumulated errors caused by large-sized measurements, ensuring volumetric accuracy. This is especially suitable for scanning large-sized objects.

ASK AN EXPERT

Is the KSCAN-MAGIC right for me?

Where can I see the KSCAN-

MAGIC in action?

KSCAN-MAGIC Specifications

| Type: | SIMSCAN 42 | SIMSCAN 30 | SIMSCAN 22 |

|---|---|---|---|

| Scan mode: | 17 blue laser crosses | 11 blue laser crosses | 7 blue laser crosses |

| Accuracy: | Up to 0.020 mm (0.0008 in) | Up to 0.020 mm (0.0008 in) | Up to 0.020 mm (0.0008 in) |

| Scanning rate up to: | 2,800,000 measurements/s | 2,020,000 measurements/s | 1,250,000 measurements/s |

| Scanning area up to: | 700 mm × 600 mm (27.6 in × 23.6 in) | 650 mm × 550 mm (25.6 in × 21.7 in) | 650 mm × 550 mm (25.6 in × 21.7 in) |

| Laser class: | CLASSⅡ (eye-safe) | CLASSⅡ (eye-safe) | CLASSⅡ (eye-safe) |

| Resolution up to: | 0.020 mm (0.0008 in) | 0.020 mm (0.0008 in) | 0.020 mm (0.0008 in) |

| Volume accuracy: | 0.015 mm + 0.035 mm/m (0.0006 in + 0.0004 in/ft) | 0.015 mm + 0.035 mm/m (0.0006 in + 0.0004 in/ft) | 0.015 mm + 0.035 mm/m (0.0006 in + 0.0004 in/ft) |

| Stand-off distance: | 300 mm (11.8 in) | 300 mm (11.8 in) | 300 mm (11.8 in) |

| Depth of field: | 550 mm (21.7 in) | 550 mm (21.7 in) | 550 mm (21.7 in) |

| Output formats: | .stl, .obj, .ply, .asc, .igs, .txt, .mk2, .umk and etc. | .stl, .obj, .ply, .asc, .igs, .txt, .mk2, .umk and etc. | .stl, .obj, .ply, .asc, .igs, .txt, .mk2, .umk and etc. |

| Operating temperature range: | -10℃–40℃ (14℉-104℉) | -10℃–40℃ (14℉-104℉) | -10℃–40℃ (14℉-104℉) |

| Interface mode: | USB 3.0 | USB 3.0 | USB 3.0 |

| Dimensions: | 203 mm × 80 mm × 44 mm (8.0 in × 3.1 in × 1.7 in) | 203 mm × 80 mm × 44 mm (8.0 in × 3.1 in × 1.7 in) | 203 mm × 80 mm × 44 mm (8.0 in × 3.1 in × 1.7 in) |

| Weight: | 570 g (1.26 lb) | 570 g (1.26 lb) | 570 g (1.26 lb) |

Hyperfine Scanning Capabilities

With 7 parallel blue laser lines, KSCAN-Magic Upgrade Series 3D scanner can accurately obtain complete data of complex objects, easily capturing every detail with a maximum resolution of 0.010 mm. This mode is ideal for detailed and intricate scans.

Metrology-grade NDT Measuring.

The KSCAN handheld 3D scanner boasts an exceptional scanning accuracy of up to 0.020 mm. When coupled with the MSCAN-L15 photogrammetry system, it excels further by achieving a volumetric accuracy of 0.015 mm + 0.012 mm/m. This technology is pivotal in driving ultra-high precision Non-destructive Testing (NDT).

KSCAN-Magic is lightweight and portable and can conduct 3D measurements anywhere and anytime regardless of vibrations, temperature, and humidity. Moreover, it is capable of 3D scanning various surfaces, performing well even on reflective and black surfaces.

INTELLIGENT EDGE INSPECTION

KSCAN Magic offers an elective module for intelligent edge evaluation. Utilizing high-precision grayscale value measurement, users can execute meticulous inspections of closed features such as holes, slots, and rectangles of stamping parts and machined parts on-site, obtaining consistent measurement results.

Contact Probing

The capability for pairing with a portable CMM K-Probe offers an intelligent solution to probe inaccessible areas and meticulously detailed parts. This crafted 3D solution provides accurate and all-encompassing results.

Pipe Measurement

Thanks to KSCAN-Magic’s various operating modes, it is capable of 3D scanning pipes of different sizes and materials. When combined with optional software, it can conduct reverse engineering and inspection for pipes, ensuring comprehensive analysis.

Fully-Automated 3D System.

The KSCAN-MAGIC can be paired with Scantech’s automated 3D inspection system, enabling effortless deployment and intelligent control to conduct automated batch inspections. This feature streamlines the inspection process and increases efficiency.

Get Your Quote

You have questions, we have the answers. Give us a few details below and we will take care of the rest.

We'd Love To Hear From You

contact us