Description

In stock and ready to ship on the same or the next business day from the local warehouse in the USA, Canada, the EU, and the UK.

CreatBot PEEK-250 3D Printer – Main Features

-

Professional Ultra-High Temperature 3D Printing

- Specifically designed for industrial-grade applications, including printing with high-performance materials like PEEK, PEI, and other engineering thermoplastics.

-

Printing Size

- 250 x 250 x 300 mm: Provides a substantial build volume suitable for creating medium to large parts.

-

480°C Nozzle

- Capable of reaching 480°C, allowing the printer to extrude a wide range of high-temperature materials.

-

200°C Heated Platform

- The build plate heats up to 200°C, ensuring optimal adhesion and stability for high-temperature filaments, preventing warping.

-

200°C Heated Chamber

- Fully enclosed and actively heated print chamber, capable of reaching 200°C, which maintains a stable print environment, reduces thermal stress, and ensures the best quality for high-performance materials.

-

Water Cooling System

- Advanced water cooling system ensures stable performance during long print jobs at ultra-high temperatures, providing consistent cooling for the extruder and mechanical parts.

-

Heat Isolation System

- Integrated heat isolation system minimizes heat loss and keeps the internal temperature stable, ensuring precision in every print.

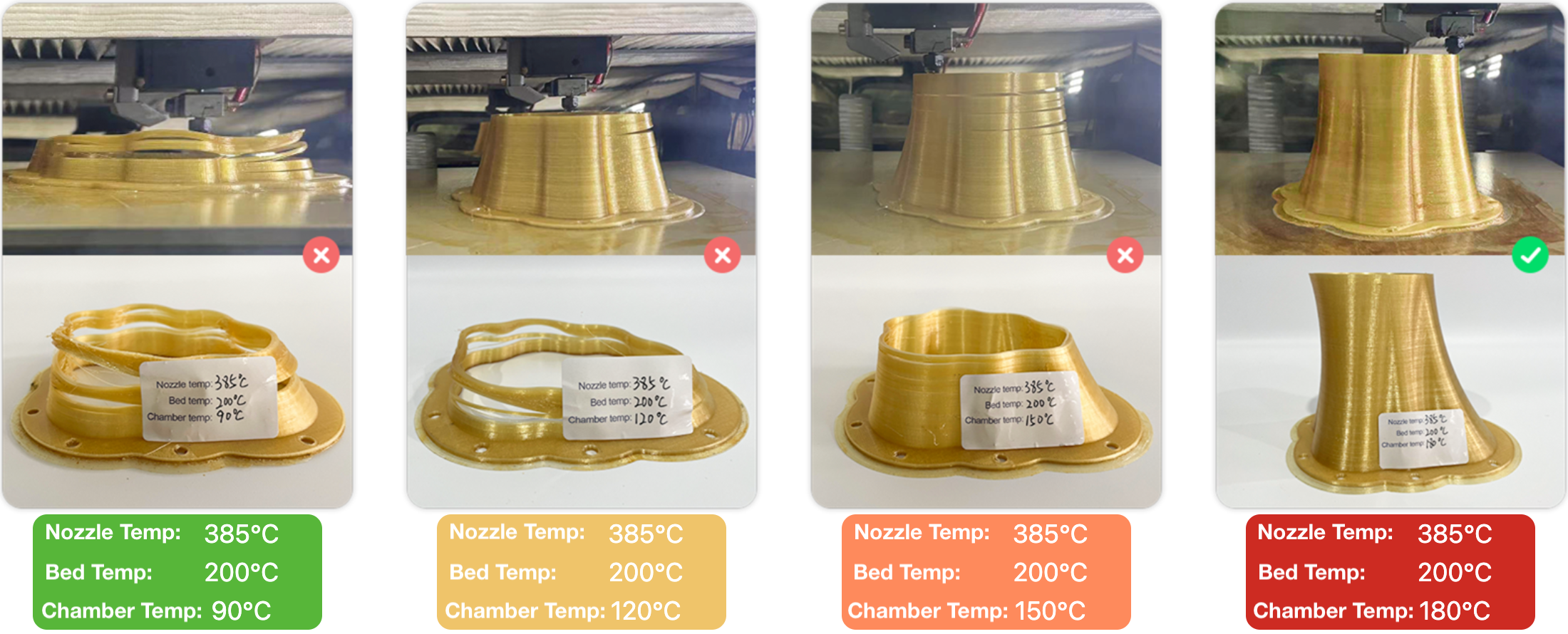

Why 180°C hot chamber is so important?

‘ 180°C ambient temperature is the required temperature for PEEK material to anneal.

Therefore, after the device prints the PEEK model, it can be annealed directly in the device.

The advantages of doing so are:

- (1)There is no need to remove the model from the platform to avoid the bottom of the model losing platform adhesion, resulting in the internal stress of the bottom model losing platform restraint, causing the bottom of the model to deform after post-processing.

- (2)Avoid shutting down and cooling the model to take out the model. There is no exchange of hot and cold environments, which causes the model to have a large temperature difference in a short period of time, and the internal stress is fixed, and it cannot be effectively post-heat treated.

- (3)After printing, the annealing treatment can be set directly inside the printer without any time delay. For example, it is set in advance to stand in a 180°C environment for 5 hours after printing, and then stand in a 120°C environment for 5 hours to fully anneal the PEEK parts.

‘¡ 180°C is the temperature at which PEI material can be perfectly printed.

- (1)Printing environment temperature requirements: Usually set between 160°C and 200°C to ensure that the material can be fully extruded and bonded and reduce the internal stress after molding to prevent cracking. The recommended ambient temperature is 180°C to improve fluidity, obtain higher combined line strength, and improve heat resistance and chemical corrosion resistance by reducing molding internal stress.

- (2)PEI has hygroscopic properties and can cause material degradation. The humidity value is required to be less than 0.02%. The drying conditions are 150°C and 4 hours of drying treatment, and the drying treatment can be carried out directly in the cavity.

- (3)PEI materials also usually need to be annealed after molding to eliminate the internal stress generated during the molding process. The advantages of direct annealing are the same as PEEK.

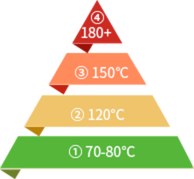

Why is it so difficult to raise the cavity temperature to 180°C+?

Through the previous knowledge popularization, we know that high-temperature cavity is a necessary condition for good molding of polymer materials such as PEEK and PEI. But why can’t the cavity temperature of many large industrial-grade equipment reach 180°C +?

1) 70-80°C is the temperature limit of most circuit boards, motors, belts and other parts. Exceeding this ambient temperature, these parts will break down. Therefore, the temperature of ordinary printers with cavity temperature is at this level.

2) 120°C is the temperature limit of high-temperature motors and belts. At the same time, they need to be well cooled, shielded and heat-insulated or heat-dissipated for circuit parts, and heat-insulated for the cavity.

3) 150°C requires a completely independent cavity closure design and heat-insulation design. In addition to the heat screen and heat-dissipation design for all heat-resistant parts, the long-term durability and heat uniformity of the heating device are also required. And the multi-layer heat insulation design of the equipment shell.

4) For an ambient temperature of 180°C-200°C, an aviation-grade heat-insulating sports protective cover is also required. The excellent sports heat-insulating material can completely isolate the air below and above the nozzle, and circulate and replace the hot air gathered in the upper cavity with the hot air in the shell under balanced pressure. Ensure that the external temperature of the shell meets the safety standards for human use.

Ultra-high temperature extruder system

Equipped with a double-tooth silicon carbide extruder, it has the characteristics of large torque, super wear resistance, and no step loss. It can print all filaments below 500°C, especially carbon fiber and glass fiber materials.

Water cooling device is necessary, which is the key to smooth printing of high-temperature filament. Hot-end is an Integrated die-casting wear-resistant nozzle, which can be replaced within 30 seconds without removing other parts or screws.

200°C thermally uniform chamber

The special spoiler device allows the hot air in the cavity to circulate 360°, ensuring that the cavity is heated evenly, and the polymer material model is evenly crystallized at any angle and perfectly formed.

Chamber thermal insulation/safety

For the first time, an aviation-grade heat-insulating sports protective cover is used in professional-grade equipment. Through clever design, multi-path heat dissipation, customized high-temperature resistant parts, and the use of multi-layer heat-insulating materials, when the chamber temperature reaches 180°C, the temperature of the front door, top door, screen area, body, and side panel area of the machine is within 40°C, ensuring the safety of users.

High temperature platform 200°C

- Aviation-grade ultra-flat platform + polymer-based coating

- Natural flatness 0.05mm

- High temperature flatness 0.1mm (cavity temperature 180°C)

- No manual or automatic leveling required, avoiding manual leveling or sensor failure in high temperature environments

One-stop annealing function

After the model is printed, there is no need to peel the model from the platform, cool it naturally, or anneal it in the annealing furnace.

You can select the “direct annealing after printing” function for the corresponding material such as PEEK, PEI, etc. on the screen in advance. You can also modify the built-in annealing temperature and time in the settings to achieve one-click annealing.

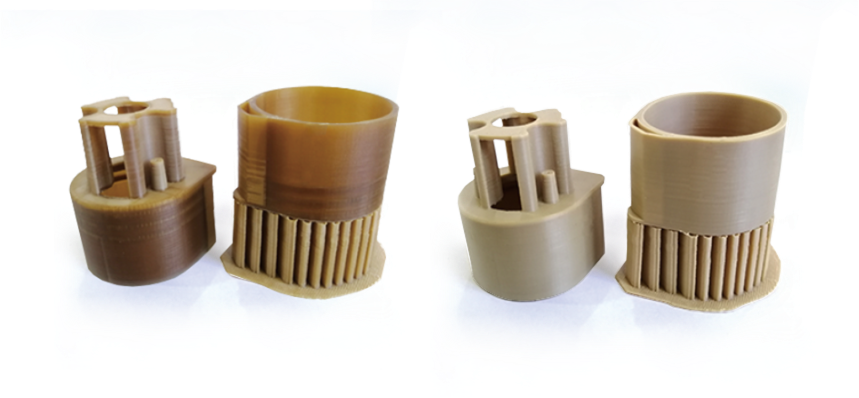

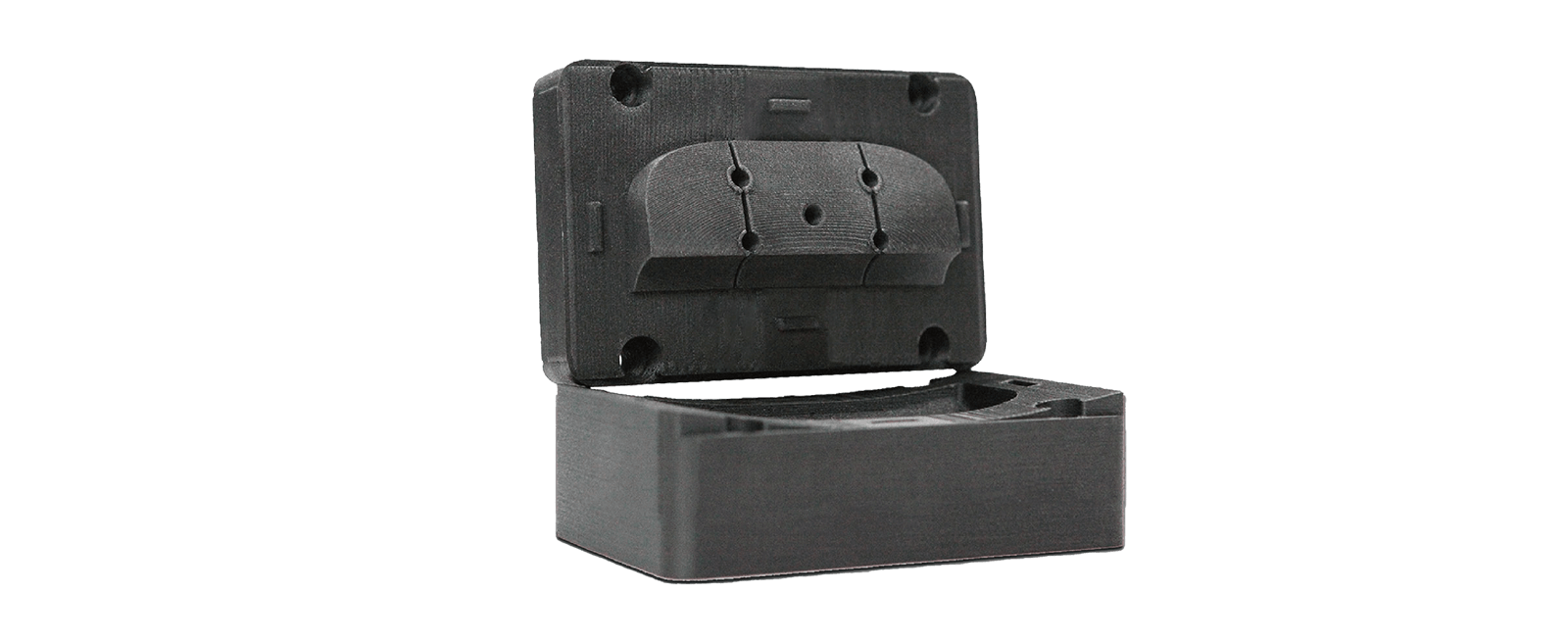

3D Printed Samples with the CreatBot PEEK-250 3D Printer

- Ready to Ship! Shipping within 1 – 2 business days via FedEx/DHL and local freight companies.

- Shipping from the local warehouse in the USA, Canada, the EU, and the UK.

- All pictures shown are for illustration purposes only. The actual product may vary due to product enhancement.