Enhanced Speed and Precision

The D1000 HS is an industrial-grade large 3D printer, boasting a build volume of 1000 x 1000 x 1000 mm. This model, upgraded from the D1000, introduces a new hotend with an impressive flow rate of 90 mm³/s. It achieves a stable printing speed of 300 mm/s, which is five times faster than its predecessor. This speed and precision make it ideal for producing large prototypes, molds, tools, and more, ensuring high-quality, functional parts within just days.

Large-Scale Production

The D1000 HS is specifically designed to handle large-scale 3D printing tasks, making it an excellent choice for industries that require durable and full-sized prototypes. This machine is perfect for producing automotive components, engineering tools, and molds that require high-strength materials like carbon fiber-infused nylon. Its massive build area eliminates the need for assembling smaller parts, enabling the creation of large, high-strength prototypes in a single print, enhancing both productivity and reliability.

Advanced Thermal & Filament Management

The D1000 HS features a 70°C heated chamber and a filament dry room, which keeps materials dry and ensures print quality for high-performance filaments like nylon and PC. The enclosed chamber minimizes external interference and noise, providing a controlled environment that helps prevent warping or deformation of printed models. The filament drying system can hold up to 5kg rolls, allowing for continuous printing without frequent filament changes.

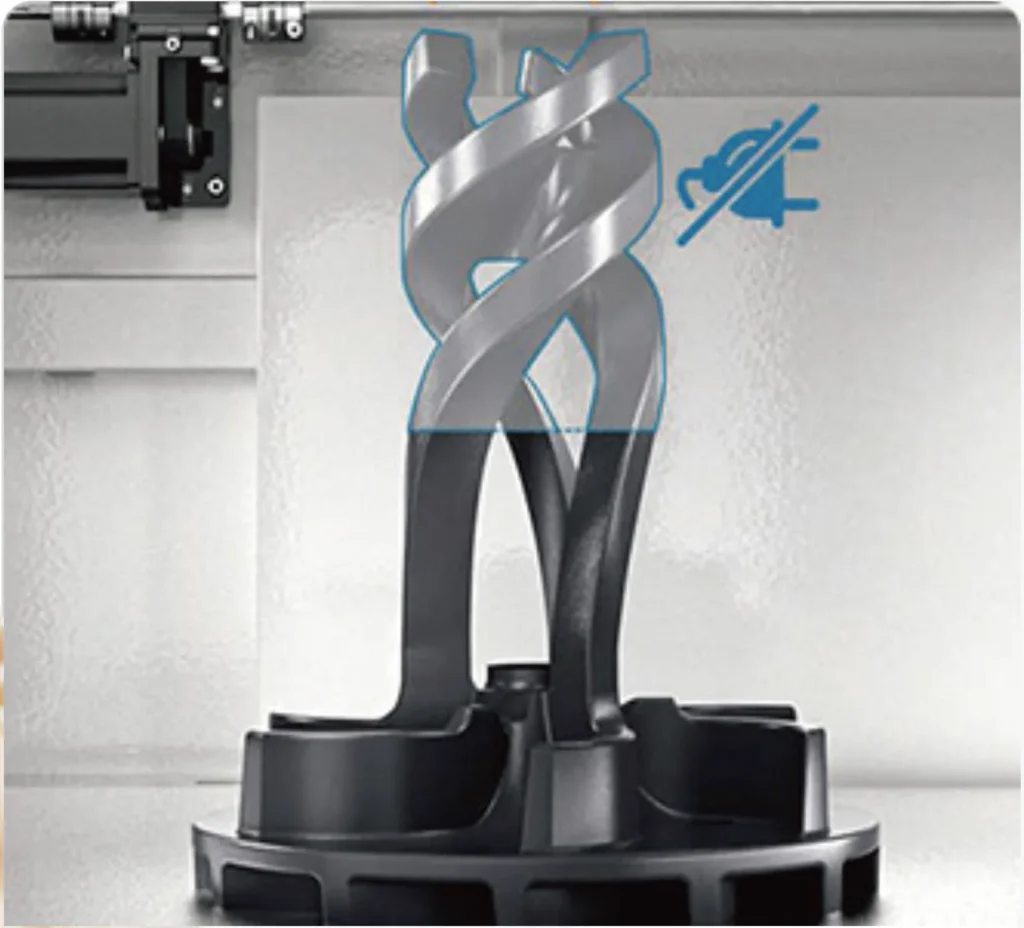

Smart Automation and Monitoring

The D1000 HS offers smart automation features such as an auto-leveling platform, outage recovery, and filament detection. The auto-leveling system uses 100 data points to ensure precise leveling, while the printer’s power outage restore feature saves the print progress and allows it to resume from the last point in case of interruptions.

Built for Durability and Reliability

Built with a full-steel frame, the D1000 HS is designed to withstand the demands of industrial printing. This robust construction ensures stability during long print jobs, while servo motors with closed-loop control enhance precision and reduce noise.

Get Your Quote

You have questions, we have the answers. Give us a few details below and we will take care of the rest.

We'd Love To Hear From You

contact us