Precision Redefined

The Artec Metrology Kit is an advanced 3D optical measuring system that offers precision up to 2 microns, making it an essential tool for industries involved in inspection, reverse engineering, and detailed measurement applications. This professional-grade photogrammetry solution ensures high volumetric accuracy, enabling manufacturers to meet rigorous quality standards.

Versatile and Integrative

Designed to seamlessly integrate into various workflows, the Metrology Kit is adaptable for use in both workshops and outdoor environments. It supports major software platforms, including Control X and PolyWorks, making it a versatile asset for professionals across different sectors.

Dual Functionality: Maximum Utility

The Metrology Kit can function independently as an optical measurement solution or serve as a reference tool to enhance the accuracy of 3D scanning over distances. By utilizing the Metrology Kit plugin, users can access a comprehensive workflow that combines 3D scanning with photogrammetry in Artec Studio.

ASK AN EXPERT

How does the Metrology Kit work?

Where can I see the Metrology Kit in person?

What software do I need?

SCHEDULE A DEMO

See the Metrology Kit in action

Test out the Metrology Kit

Speak with an expert face-to-face

Artec Metrology Kit Specifications

| 3D Point Resolution: | up to, 0.2mm | 3D Point Accuracy: | up to, 0.1mm |

| Processing: | On-board real time processing | Color Resolution: | 2.3 Megapixels |

| Volume Capture Zone: | 160,000 cubic centimeters | Position Sensors: | Built-in 9 DoF inertial system |

| 3D Reconstruction Rate: | 80 Frames per Second | Multi-core processing: | NVIDIA Jetson TX2 |

| Power Source: | Rechargable Battery on board | Connectivity: | Wireless, ethernet, SD Card |

| Display: | Built-in touch panel screen | Structured Light Source | VCSEL |

Compact and Portable Design

Housed in a durable, portable case, the Metrology Kit is designed for mobility, enabling measurements in challenging environments. Its dynamic referencing capability allows for capturing objects in motion, making it ideal for sites where traditional measuring tools may fall short.

Enhanced Inspection Capabilities

With its high-accuracy optical measurement system, the Artec Metrology Kit simplifies the inspection of various components, including aircraft parts and industrial machinery. This system enables reliable and efficient inspections, ensuring products meet stringent quality requirements.

The Metrology Kit excels in analyzing the deformation characteristics of materials under varying conditions. It is particularly effective for assessing geometrical changes in components like storage tanks and prototypes, where rapid measurement times are critical.

Integration with Existing Software

The kit’s compatibility with industry-leading software solutions like Geomagic Control X and PolyWorks allows for a seamless integration into existing workflows. This flexibility ensures users can maximize the benefits of the Metrology Kit while working within their established systems.

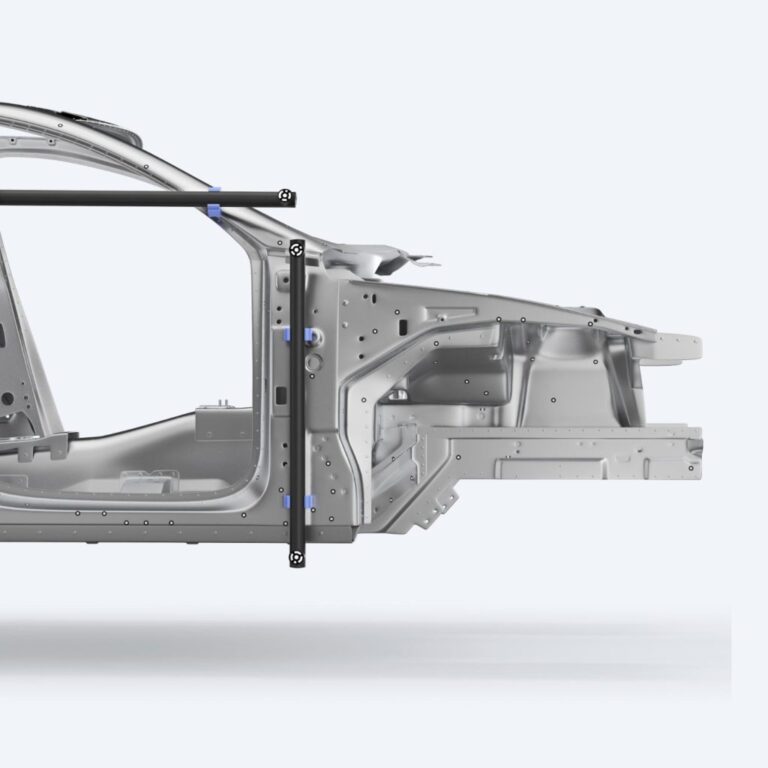

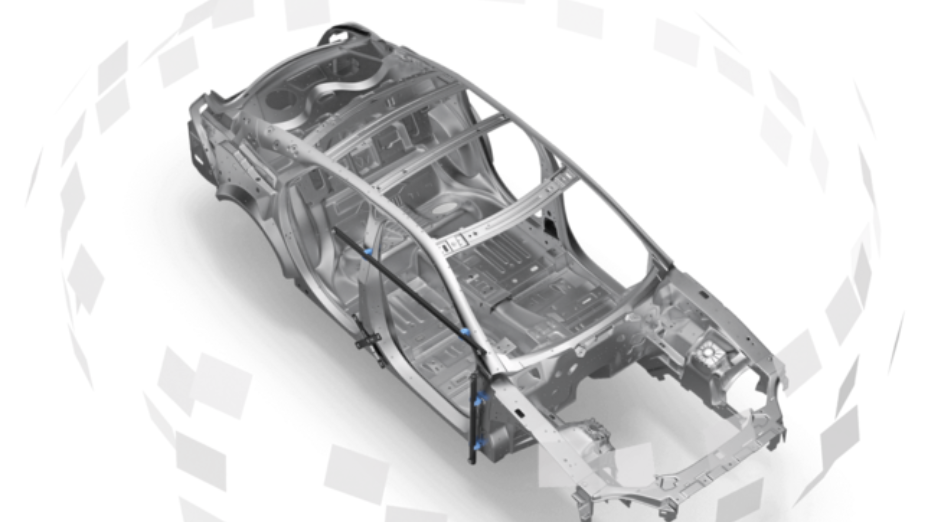

Applications Across Industries

The Artec Metrology Kit finds applications in diverse sectors, including automotive, aerospace, and offshore engineering. Its portability and rapid measurement capabilities make it invaluable for inspecting components in remote or unstable environments.

Customizable Options for Varied Needs.

Available in both Entry and Professional versions, the Artec Metrology Kit caters to different engineering requirements. Each version includes various features tailored to specific use cases, allowing users to choose the most suitable option for their needs.

Get Your Quote

You have questions, we have the answers. Give us a few details below and we will take care of the rest.

Frequently Asked Questions

What is the Artec Metrology Kit used for?

The Metrology Kit is an optical coordinate measuring system that is mostly used for different types of inspection – roundness inspection, sheet-metal inspection, and fixture inspection. Analysis – deformation analysis, tolerance analysis, 3D process analysis. And also referencing for other measurement systems. It can also be used for part alignment, CAD comparison, and other optical measurement usage applications.

What is the general workflow when using the Artec Metrology Kit?

Working with the Artec Metrology Kit begins with object preparation using targets, reference bars, and other accessories required for measurement, and then image acquisition, image transfer, image processing, and 3D-coordinates calculation for the generation of a point cloud.

Can the Artec Metrology Kit be used as a substitute for a metrology-grade 3D scanner?

The Artec Metrology Kit provides very accurate measurements over distance. However, it does not produce dense point clouds like 3D scanners do. Depending on your use case, you may want to use one or the other, or in a combined workflow.

In what industries is the Artec Metrology Kit used?

Because processes like reverse engineering and inspection occur in so many processes, the use of optical systems like the Artec Metrology Kit transcends any one particular industry. The Metrology Kit has found use in general industry, aerospace, automotive, wind energy, railway construction, and many more industries.

We'd Love To Hear From You

contact us