CreatBot

PEEK-250

Premier Ultra-High Temperature Printer

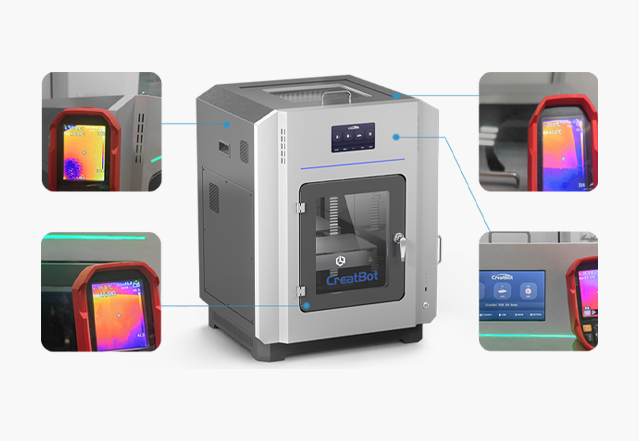

The PEEK-250 is the ultimate high-temperature 3D printer for professionals. With advanced features like a 200°C heated chamber, 480°C nozzle, and integrated annealing functionality, it delivers exceptional performance for ultra-performance materials like PEEK, PEI, and moreall in a desktop-sized machine.

High-Temperature Capabilities

As the world’s first desktop high-temperature 3D printer with a maximum hot chamber of 200°C, the PEEK-250 offers unique advantages for processing advanced materials. The printer reaches a hot chamber temperature of 180°C in just 20 minutes, which is essential for the annealing process of PEEK materials. This ability allows users to anneal the printed models directly inside the device, eliminating the need for post-printing transfers that can lead to deformation and loss of adhesion.

Benefits of Direct Annealing

LIVIS is a visual inspection system suitable for any manufacturing unit. It offers users pre-combined datasets that are industry and process specific, and aso uses custom proprietary vision models in order to provide high accuracy with less annotated data. The system can be easily integrated into existing factory machines & requites minimal hardware dependencies. For a fully autonomous solution, may easily integrate with any mechanical systems like SPM and robots.

High-Temperature Printing: Overcoming Challenges for Perfect Results

The PEEK-250 employs advanced engineering techniques, such as aviation-grade heat insulation and specialized cooling systems, to protect sensitive parts while allowing the chamber to reach high temperatures. This innovative design is crucial for successfully printing high-performance polymers like PEEK and PEI, which require elevated temperatures for optimal results.

Talk with Our Experts

User-Friendly Features

With a 200°C thermally uniform chamber and innovative design elements, the PEEK-250 ensures consistent heating and safety for the user. The specially designed spoiler allows for 360° circulation of hot air, promoting even heating and crystallization of printed materials. Furthermore, the aviation-grade heat-insulating cover maintains external temperatures within safe limits, enhancing user safety.

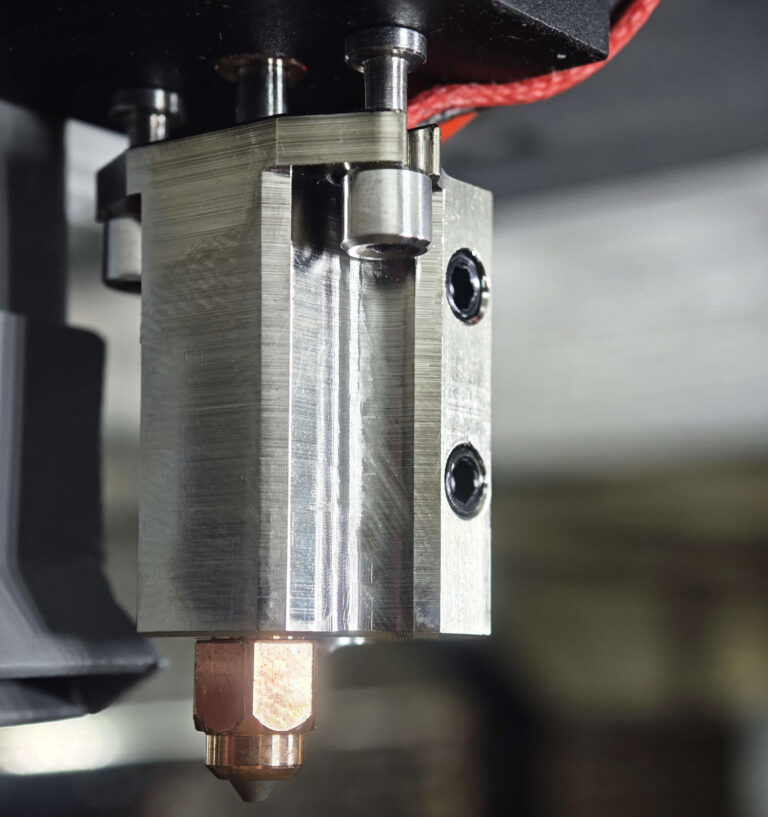

Advanced Extruder System

The PEEK-250 is equipped with a high-performance double-tooth silicon carbide extruder capable of printing with all filaments up to 500°C. This extruder boasts large torque and superior wear resistance, enabling it to handle challenging materials such as carbon fiber and glass fiber composites. The printer’s integrated cooling system for maintaining smooth operation when printing high-temperature filaments.

Partner with Us to Step into the World of 3D

We’re happy to answer any questions you may have and help you determine which of our product or services best fit your needs.

Not Sure Where to Start?

Fill out a Contact Form

Schedule a Demo

Explore New Technology!

Contact Us Today

Find Us Here

2901 Auburn Rd, Auburn Hills, MI 48326

Get in touch

Available Hours

Mon- Fri: 9am- 5pm