CreatBot

F430 NX

Pioneering Excellence in Industrial 3D Printing

The CreatBot F430 NX is a professional-grade 3D printer built for industrial demands, offering high-speed precision and versatility. Featuring IDEX dual extruders, a 420°C hotend, and a heated chamber, it ensures accuracy and reliability for prototyping, manufacturing, and advanced engineering applications.

Precision with Heat

High-temp build chamber allows for accurate parts every time

Durable Materials

Stong materials that can handle engineering tasks in many applications

High-Temperature 420°C

The CreatBot F430 NX features an advanced high-temperature hotend capable of reaching an impressive 420°C. Engineered with one-piece die-cast memory alloy and a super wear-resistant nozzle, this hotend ensures reliable and consistent performance across a broad range of materials. Compatible with PLA, ABS, ASA, PC, nylon, carbon fiber, and glass fiber, it offers exceptional versatility for various industrial applications. Designed for longevity, the nozzle maintains its integrity with less than 10% wear even after printing carbon fiber materials continuously for 2,000 hours, making it a standout choice for high-demand projects.

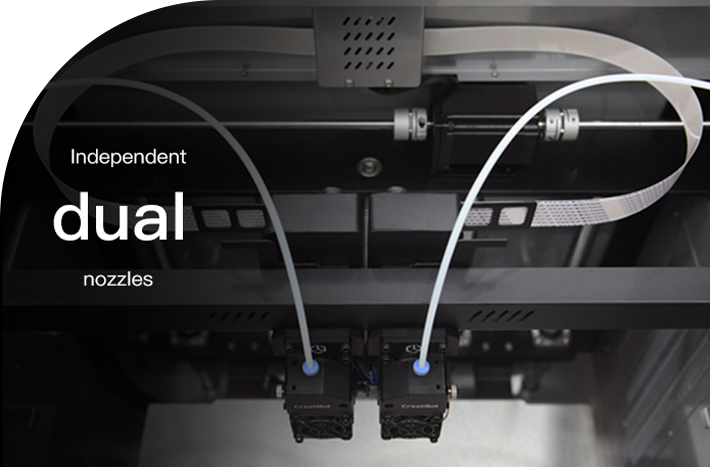

Independent Dual Extruders (IDEX)

The CreatBot F430 NX is equipped with Independent Dual Extruders (IDEX), making it a game-changer for engineering-grade material printing. This advanced system allows for the use of independent support materials, ensuring exceptional quality and precision for complex designs. The IDEX setup also enables versatile printing modes, including copy, mirror, and backup mode printing, enhancing productivity and enabling simultaneous or symmetrical part production. This innovative feature makes the F430 NX a reliable and flexible solution for demanding industrial applications.

Superior Dimensional Accuracy

The CreatBot F430 NX is meticulously engineered to deliver exceptional dimensional accuracy with a tolerance of ±0.2mm or ±0.002mm per mm of travel, ensuring industrial-grade precision. Its high-precision machined structures and tight tolerances make it ideal for printing the largest parts in engineering-grade materials. The F430 NX effectively eliminates issues like warping and poor layer adhesion, enabling the creation of massive, complex designs with unmatched accuracy and reliability. This level of precision ensures that every print meets the most demanding industrial standards.

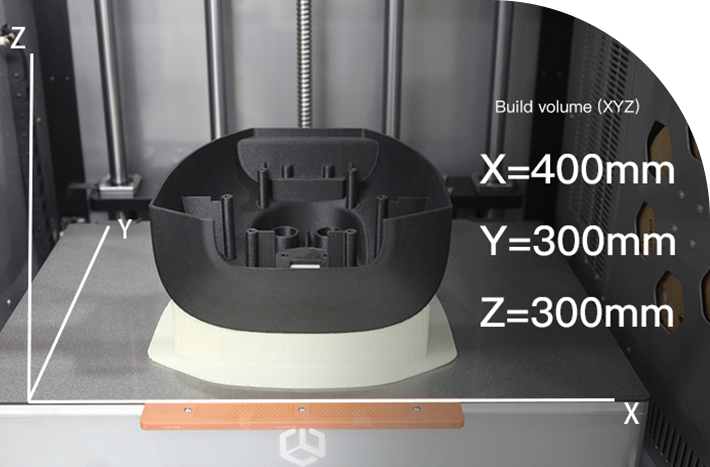

Big Build Volume

The CreatBot F430 NX boasts an impressive build volume, with single-printing dimensions of 400 x 300 x 300 mm. When using support materials, the build size reaches 360 x 300 x 300 mm, accommodating a wide range of production needs. This expansive printing capacity surpasses most professional-grade 3D printers on the market, making it ideal for creating large parts, prototypes, and complex designs with ease and precision.

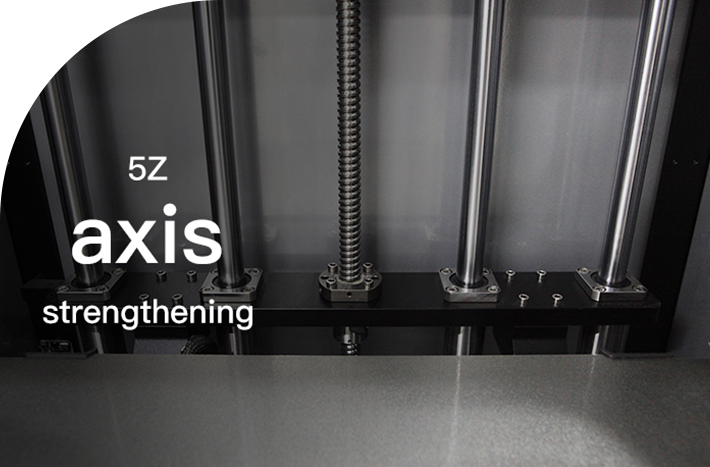

Z-Axis Reinforcement

The CreatBot F430 NX features a reinforced Z-axis design for unparalleled stability and precision. Its back side is equipped with a high-precision ball screw and four reinforced optical axes, ensuring tight fit and synchronized movement. This robust configuration delivers uniform and impurity-free model surfaces, significantly improving the surface quality of engineering-grade materials. The Z-axis reinforcement is key to achieving reliable performance and exceptional dimensional accuracy for demanding 3D printing applications.

High-Resolution Touch Screen

The CreatBot F430 NX is equipped with a 5-inch high-resolution capacitive touch screen, offering a seamless and intuitive user experience. This responsive interface ensures no delays in operation and provides a delicate touch for precise control. The user-friendly design simplifies the management and operation of the printer, making advanced 3D printing accessible and efficient for professionals. Additionally, the full-color display enhances usability by providing clear, detailed visuals for real-time monitoring and adjustments.

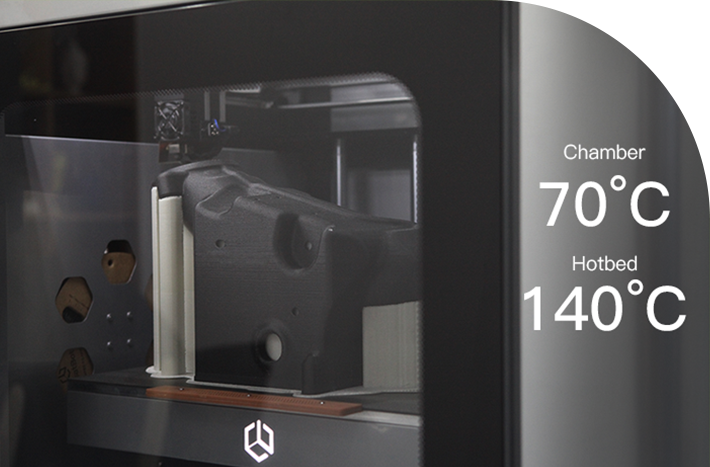

Active Heating of Hot Bed/Chamber

The CreatBot F430 NX is equipped with an active heating system for both the hot bed and the chamber, ensuring optimal performance with engineering-grade materials. The heated bed can reach temperatures of up to 140°C, while the chamber heating achieves 70°C. This advanced thermal management system effectively prevents shrinkage and cracking during the printing process, enabling materials like ABS, ASA, PC, Nylon, and UltraPA-CF to achieve perfect formation with maximized mechanical properties. This feature guarantees dimensional accuracy and structural integrity in every print.

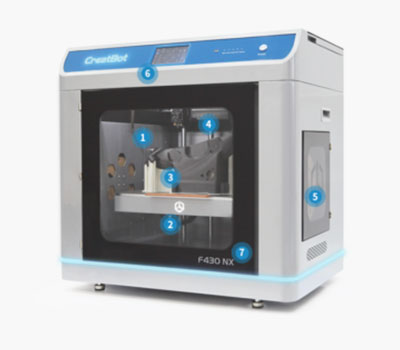

1. Powerful Extrusion System

- Independent Dual Extruders (IDEX) for advanced multi-material printing.

- Durable titanium alloy extrusion head for enhanced longevity.

- Quick-swap hotends for minimal downtime.

- High-temperature 420°C silicon carbide nozzle for versatile material compatibility.

2. Active Heated Chamber

- Chamber capable of heating up to 70°C for consistent thermal performance.

- Heated bed reaches up to 140°C to support high-temperature materials.

3. Massive Print Volume

- Single Printing: 400 x 300 x 300 mm.

- Dual Printing: 360 x 300 x 300 mm.

- Copy Mode: 225 x 300 x 300 mm.

- Mirror Mode: 190 x 300 x 300 mm.

4. High-Speed Execution Ready

- Adjustable speed ranging from 100 to 300 mm/s for diverse project needs.

- Reinforced Z-axis for precision and stability during high-speed operations.

5. Material Operations System

- Built-in filament drying room with a controlled temperature of 70°C.

- Automatic filament switching for uninterrupted printing.

- Supports engineering-grade materials, including carbon and glass fiber filaments.

6. User Experience

- Flexible build plate for hassle-free part removal.

- Built-in camera for remote monitoring.

- Intuitive 5-inch capacitive touchscreen for easy operation.

- Connectivity via WiFi or Ethernet for seamless integration.

- Ambient status light for real-time printer status updates.

7. Safety Features

- Low-noise operation at 50 dB for quieter working environments.

- HEPA and carbon filters for safe air quality.

- Fault signal light for immediate error notifications.

- Advanced thermal runaway protection for enhanced safety.

CreatBot F430 NX Specifications

| PRINTING | |

|---|---|

| Print Technology | FFF |

| Build Volume | Single printing: 400*300*300 mm Dual printing: 360*300*300 mm Copy mode: 225*300*300 mm Mirror mode: 190*300*300 mm |

| Number of Nozzles | Dual |

| Independent Dual Nozzles | Yes |

| Min Layer Height | 0.05 mm |

| Filament Diameter | 1.75 mm |

| Filament Compatibility | PLA, ABS, Carbon, Nylon, UltraPA, UltraPA-CF, PET-CF, PC, TPU, ASA, PETG, etc. |

| Nozzle Diameter | 0.4 mm (0.3, 0.5, 0.6, 0.8, 1.0 mm) |

| Print File Type | GCODE, STL, STEP |

| TEMPERATURE | |

|---|---|

| Max. Nozzle Temperature | 420 °C |

| Max. Bed Temperature | 140 °C |

| Max. Chamber Temperature | 70 °C |

| SPEED | |

|---|---|

| Printing Speed | 50-300mm/s |

| HARDWARE | |

|---|---|

| Air Filter | HEPA+Carbon |

| Print Bed | Removable magnetic platform (base on high-precision aviation aluminum plate) |

| Print Surface | PEI sheet + PEI coating |

| Mainboard | 32 bits |

| X/Y Min & Max | Photoelectric switch |

| SOFTWARE | |

|---|---|

| Software Bundle | CreatWare, Simplify 3D, Cura, Slice 3r |

| Supported File Types | STL, OBJ, AMF |

| Operating Systems | Windows All; Mac OS |

| SPECIAL FUNCTION | |

|---|---|

| Outage Restored | Save data when power is off |

| Filament Detection | Pause printing when filament clock or run out |

| Automatic Leveling Bed | Yes |

| Automatic Shutdown | Turn off the power when printing is complete |

| Camera Control | Yes |

| WiFi & Ethernet | Yes |

| Breathing Light | Yes |

| Backup Model | Yes |

| ELECTRICAL | |

|---|---|

| Power Requirements | 240V, 50-60Hz / 110V, 50-60Hz |

| Max. Power | 240V: 3200W / 110V: 2500W |

| Screen | 5″ Touch Screen |

| Connectivity | USB/USB disk / WiFi |

| SIZE & WEIGHT | |

|---|---|

| Product Dimensions & Weight | 780*550*800 mm / 78 kg |

| Packaging Dimensions & Weight | 865*635*1055 mm / 107 kg |

Partner with Us to Step into the World of 3D

We’re happy to answer any questions you may have and help you determine which of our product or services best fit your needs.

Not Sure Where to Start?

Fill out a Contact Form

Schedule a Demo

Explore New Technology!

Contact Us Today

Find us Here

2901 Auburn Rd, Auburn Hills, MI 48326

Get in touch

info@rev1tech.com

Available Hours

Mon- Fri: 9am- 5pm